ResMetrics’ quality control systems and state-of-the-art analytical laboratory make current tracer technologies more accurate and robust. We ensure that all raw data delivered to our customers is free from errors associated with poor tracer injection measurements and inadequate analytical instrumentation. In order to accomplish this task, we have implemented a number of enhancements to improve the accuracy of tracer data.

– Tracer screening and calibration

– Tracer injection Automatic Flow-Metering

– iPhone/Android Sampling App

– High-Performance Analytical Lab

– PetroXY web application to interpret tracer data

– Cloud Data Delivery

Chemical tracers are selected based on their ability to mimic the behavior of the carrier fluid that they are injected into. For example, water phase tracers dissolve readily when added to a water mixture, and oil phase tracers dissolve readily when added to a hydrocarbon mixture.

In order to provide quantitative tracer data to our clients, all chemical tracers undergo a rigorous screening process to ensure performance within the reservoir. Each tracer type is subjected to a barrage of tests in the laboratory and in the field before being pumped commercially. Chemical purity, thermal stability, solubility, reservoir adsorption, and chemical reactivity are just a few examples of what we look for when testing our tracers.

Our rigorous quality control measures guarantee that the correct tracer is pumped into the correct stage at the correct rate.

Each unique tracer is identified with an RFID tag that is tracked from the warehouse to the well site. Technicians scan the appropriate RFID tag for each traced interval to ensure correct delivery of each unique tracer. Our tracer pumps are equipped with flow monitoring and control capabilities to ensure consistent tracer injection.

Post job reports are delivered to the client immediately following each job and are automatically uploaded to the PetroXY database.

The success of any tracer program greatly depends on ensuring that samples are collected on time. Our iPhone/Android app greatly improves the sampling process. QR codes on every sample bottle allows the sampling technician to scan each sample using their mobile device and record:

– Sample Date

– Sample Time

– Sample GPS Location

– Produced volume (oil/water)

Engineering teams can actively monitor the sampling process via the PetroXY web application and can be notified automatically when a sample is not collected on time.

High-sensitivity analytical instrumentation provide quantitative tracer results that accurately profile fluid flow within the reservoir. Our laboratory is outfitted with the latest in UHPLC (ultra-high performance liquid chromatography).

The addition of the HRAM spectrometer to the system provides unparalleled sensitivity, resolution, and accuracy when detecting tracer compounds. Our laboratory offers the following advantages:

– Increased data precision

– Reduction in human error

– Quantifiable results

– Improved turnaround time

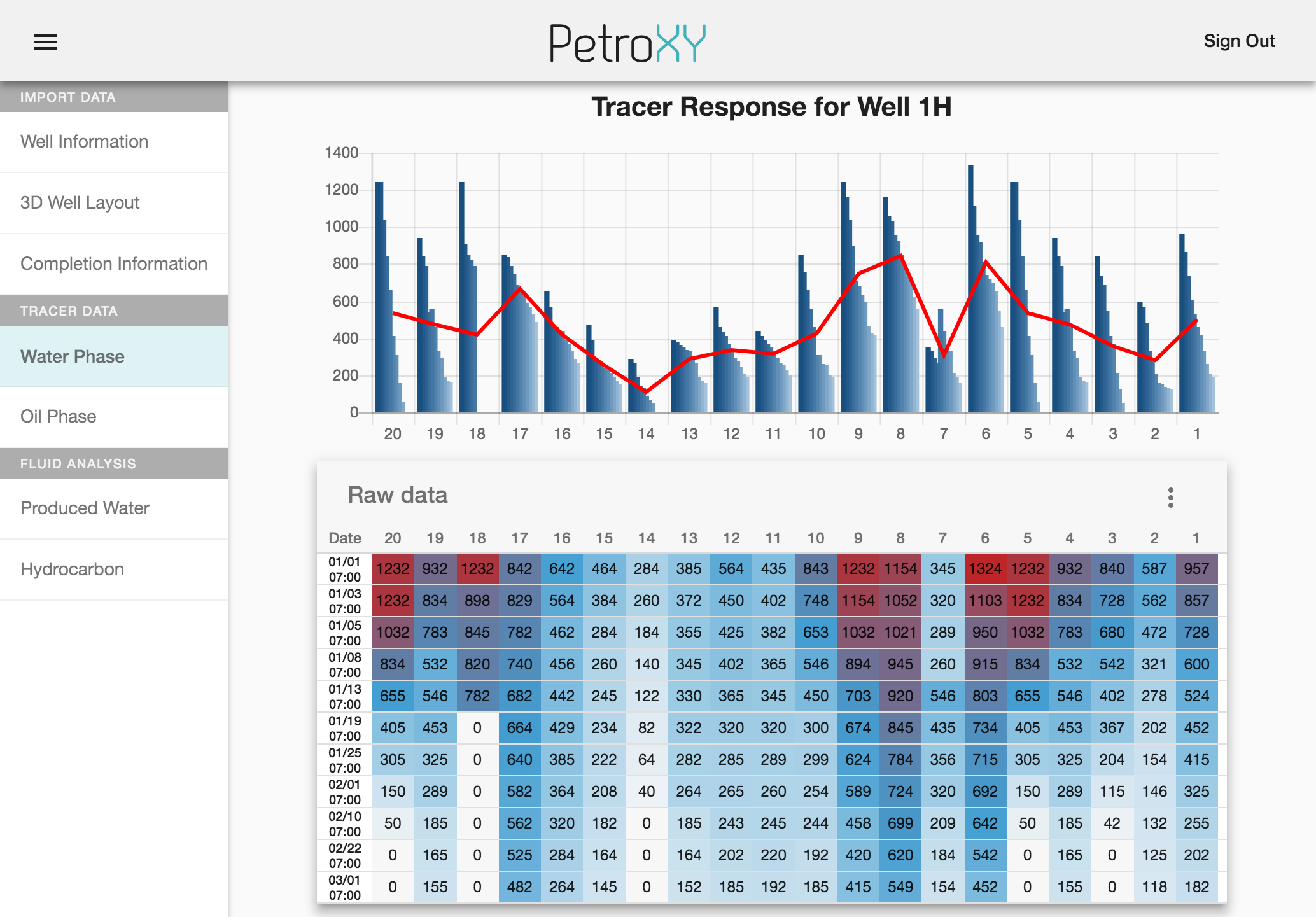

PetroXY is a web application that integrates tracer data with drilling, completions, and reservoir data. Engineering and subsurface teams can log in to PetroXY to view tracer data and upload their own unique data sets.

Completion Evaluator module aids in visualizing tracer data and evaluating the efficiency of multi-stage horizontal completions. Users can import drilling data, log data, completion data, and frac data to better understand the flowback signature of each tracer. Wellbores can be plotted in 3D to highlight fracture interference between wells.

IOR/EOR Evaluator module aids in visualizing the sweep efficiency of an IOR/EOR project. Quantitative analysis of tracer data is carried out using RTDA (Residence Time Distribution Analysis) and can determine many flood properties: volumetric sweep efficiency from injector to producer, flow geometry, and remaining oil saturation, to name a few. Injection and production rates and water cut are required to perform this analysis.

While we understand the importance of data quality, we also understand the importance of delivering data to the client quickly and efficiently. Gone are the days of delivering important data through emails with excel attachments.

All tracer data is uploaded to the cloud (PetroXY) immediately after lab analysis so that our clients can receive immediate feedback on their well’s production. Since tracer data is typically captured over months (or even years), engineers are automatically notified when new tracer data is available. Error-checking protocols are in place to ensure reliability of data.

The client can also download raw tracer data so that it can be imported directly into another software platform.