By: Wei Tian and Alex Darnley

Introduction

Horizontal drilling and hydraulic fracturing sparked the boom of exploration and development in shale reservoirs. In such stimulation processes, horizontal wells are drilled divided into equal segments and fractured sequentially from “toe” to “heel”. Over the years engineers have refined their technique in stimulating shale reservoirs, however, their understanding of fracture geometry and flow contribution is limited.

Chemical tracers are used during multi-stage hydraulic fracturing treatments to tag individual frac stages with a unique chemical tracer. A tracer is simply a chemical compound that is designed to faithfully follow the flow path of its carrier fluid while travelling through the reservoir. Water tracers are used to tag the frac fluid injected during the treatment, while hydrocarbon tracers are used to tag the oil or gas in place in the reservoir. The tracers are HSE-friendly, non-toxic, and are easy to inject during the fracture treatment without any negative impact on completion.

To obtain quantitative data regarding the fracture diagnostics, tracers are injected at a constant concentration (ppm or gpt) during the entire frac treatment. Since each frac stage is traced at the same concentration and dilution is assumed as the only mechanism influencing tracer concentration, the flow back concentration of each individual tracer is directly proportional to the flow rate of frac stages tagged by the tracer. This data can be used to benchmark completion designs and to better understand the geological “sweet spots” within a typical shale formation by looking at stage tracer recoveries.

The typical actionable datasets gathered via this tracer evaluation include:

Operational Procedures

Tracer Selection

ResMetrics tailors each evaluation to accomplish the operator’s target objectives for fracture diagnostics while ensuring that each tracer chemical is compatible with the formation of interest. All chemical tracers used for fracture analysis have gone through rigorous laboratory and field screening. Selected tracers should behave as expected and guarantee reliable and repeatable analysis. Chemical purity, thermal stability, and tracer partitioning are just a few examples of screening criteria, which determines the field viability of a tracer compound.

Tracer Injection

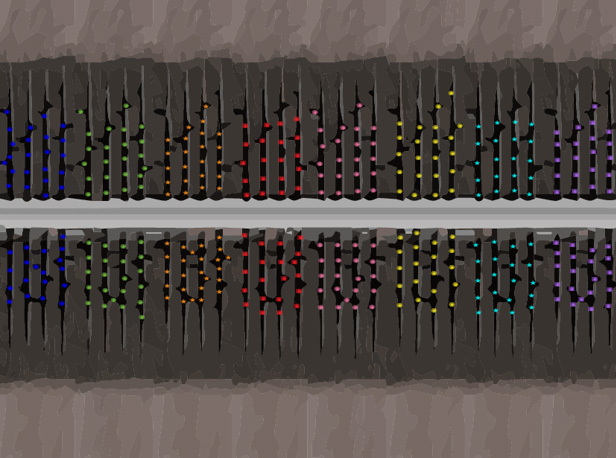

ResMetrics has developed a unique tracer injection pump to accurately inject chemical tracers downhole during a hydraulic fracturing treatment. This pump is specially designed to monitor and control the injection rate of tracer solution using a built-in flowmeter. The tracer injection rate is automatically adjusted based on the real-time clean rate dictated by the frac van. In addition, the pump includes an RFID scanner which scans the tracer chemical before being pumped. This ensures that the correct tracer is pumped on the assigned stage.

This process greatly improves the accuracy of tracer injection and guarantees that the same concentration of tracer is being injected into every individual stage. A post-job report is delivered to the customer after the injection job.

Sampling

The sampling of produced fluids during flowback and production is one of the most important components during a tracer test but is often the most overlooked. In order to obtain accurate sample data, samples should be taken frequently and on a pre-determined schedule based on the well’s production rate. Samples should never be caught from a flowback tank containing produced fluids originating from multiple wellheads. It is best to sample from a test separator containing a moving stream of fluids from only one individual wellhead. If a test separator is not available, a commingled wellhead sample can be caught and separated in the lab.

For mass balance to be accurate (tracer in vs. tracer out), the flowback and production data for the individual well should be accurately recorded as well. Water and oil (or gas) samples are collected during the flow back period and sent to the lab for analysis. Concentration for all tracers in the samples will be measured and recorded.

Deliverables

Fracture analysis is carried out using tracer flowback data. This analysis is primarily based on mass balance. Integrating tracer concentration with water and oil production rates yields the total mass of tracer recovered from each stage. The ratio of recovered tracer mass to the total injected tracer mass reveals the stage load fluid cleanup efficiency and oil tracer recovery. Comparing the concentration of each tracer yields the stage inflow contribution of frac fluid and hydrocarbon production. Such information can further yield the heel to toe ratio. All interpretation as well as raw tracer data will be uploaded to our cloud-based platform (PetroXY) for review.